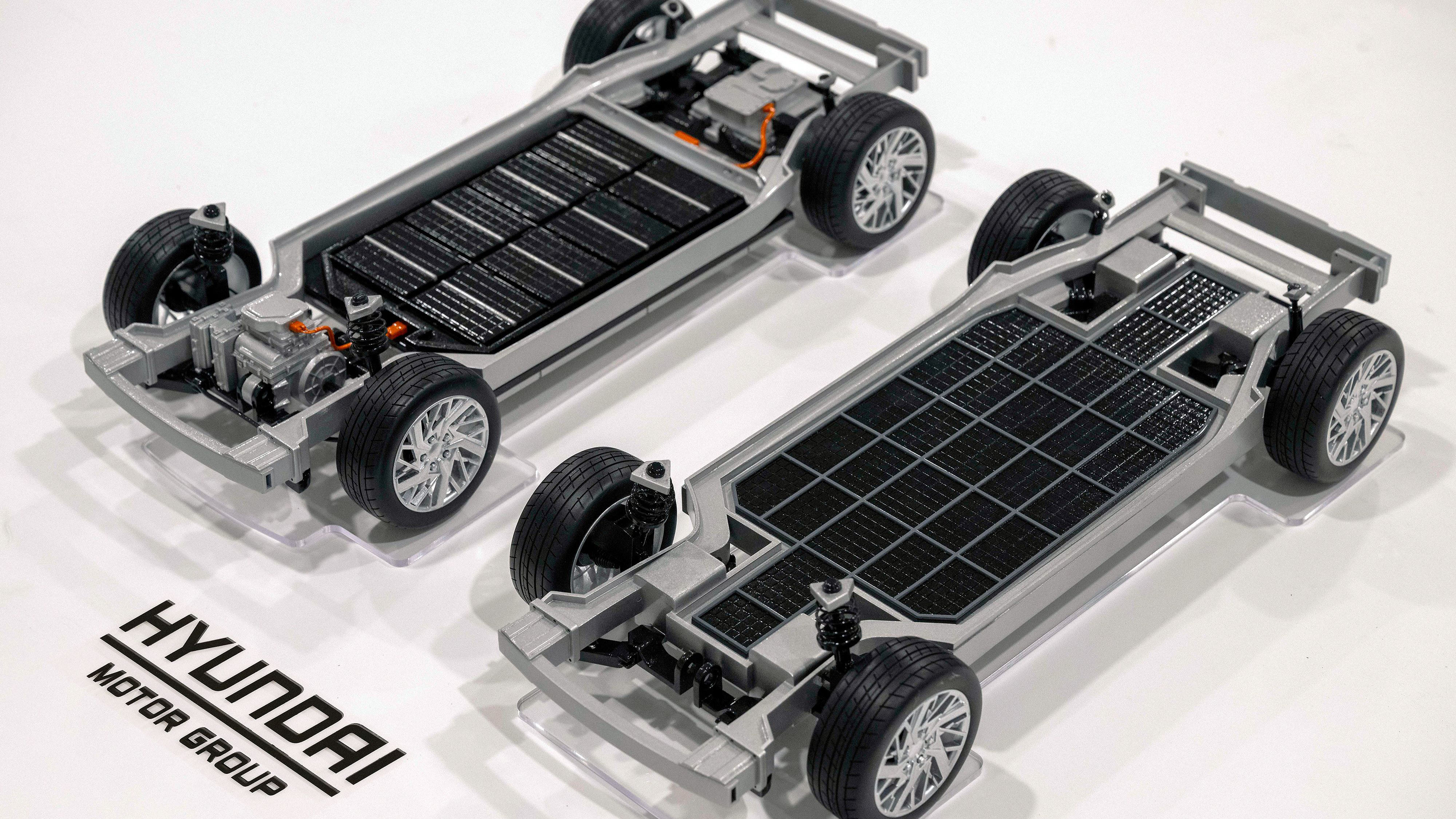

Hyundai and Kia have unveiled a radical new EV drivetrain system

Called the ‘Uni Wheel’, the pair says this could be used on pretty much anything with wheels

Hyundai and Kia have linked up to reveal a new universally adaptable drivetrain system called the ‘Uni Wheel’, which aims to change both personal and commercial mobility and deep-fry your mind.

The new system integrates pre-existing drivetrain technology that has essentially been re-engineered to move the main drive system components to the vacant area within a car’s wheel hub. Want to understand how it works? Get your nerd hat on, it’s time for a science lesson.

In a traditional combustion-powered car, the power is sent from the engine through the transmission and then to the wheels using drive shafts and CV joints. In an EV, the electric motor and reduction gear substitute for the engine and the transmission, but the rest of the process remains the same.

The Uni Wheel looks to change this final step by repositioning the reduction gear in an EV to inside the wheel hub and then fitting ‘compact’ individual motors closer to each wheel. This would not only reduce the size of the drive shafts but also the amount of overall floor space used. That means more cabin space for crisps and crumbs to claim as their residence.

OK, ready to get even geekier?

What then allows the Uni Wheel to work is a ‘planetary’ gear configuration, which consists of a centrally-located ‘sun’ gear, four ‘pinion’ gears on each side, and a ‘ring’ gear that sits on the outer edge, posing as the asteroid belt in this particular section of the Solar System.

The power generated by the motor is first sent to the sun gear, which is then relayed to the pinion gears to move the ring gear. The ring gear, which is connected to the actual wheels of the car, then springs into life and enables drive. Keen engineering fanatics will also note that this system could even move the torque vectoring game forward since each wheel basically has its own engine.

The South Korean power couple also says this will have a positive impact on ride comfort since the drivetrain works closely with the multi-axis suspension to ‘stabilise’ the vehicle with quicker bursts of power and torque over rougher surfaces.

The technology will continue to be refined with a view to incorporating it into future products and has the potential to be applied to anything with wheels as small as four inches or as large as 25.

That means it can even be used on different types of mobility solution, ranging from bicycles to wheelchairs. We're left wondering if it could enable a new racing series for delivery robots. ‘Formula Robot’ certainly has a ring to it, no?

Top Gear

Newsletter

Thank you for subscribing to our newsletter. Look out for your regular round-up of news, reviews and offers in your inbox.

Get all the latest news, reviews and exclusives, direct to your inbox.

Trending this week

- Car Review

BMW 1 Series