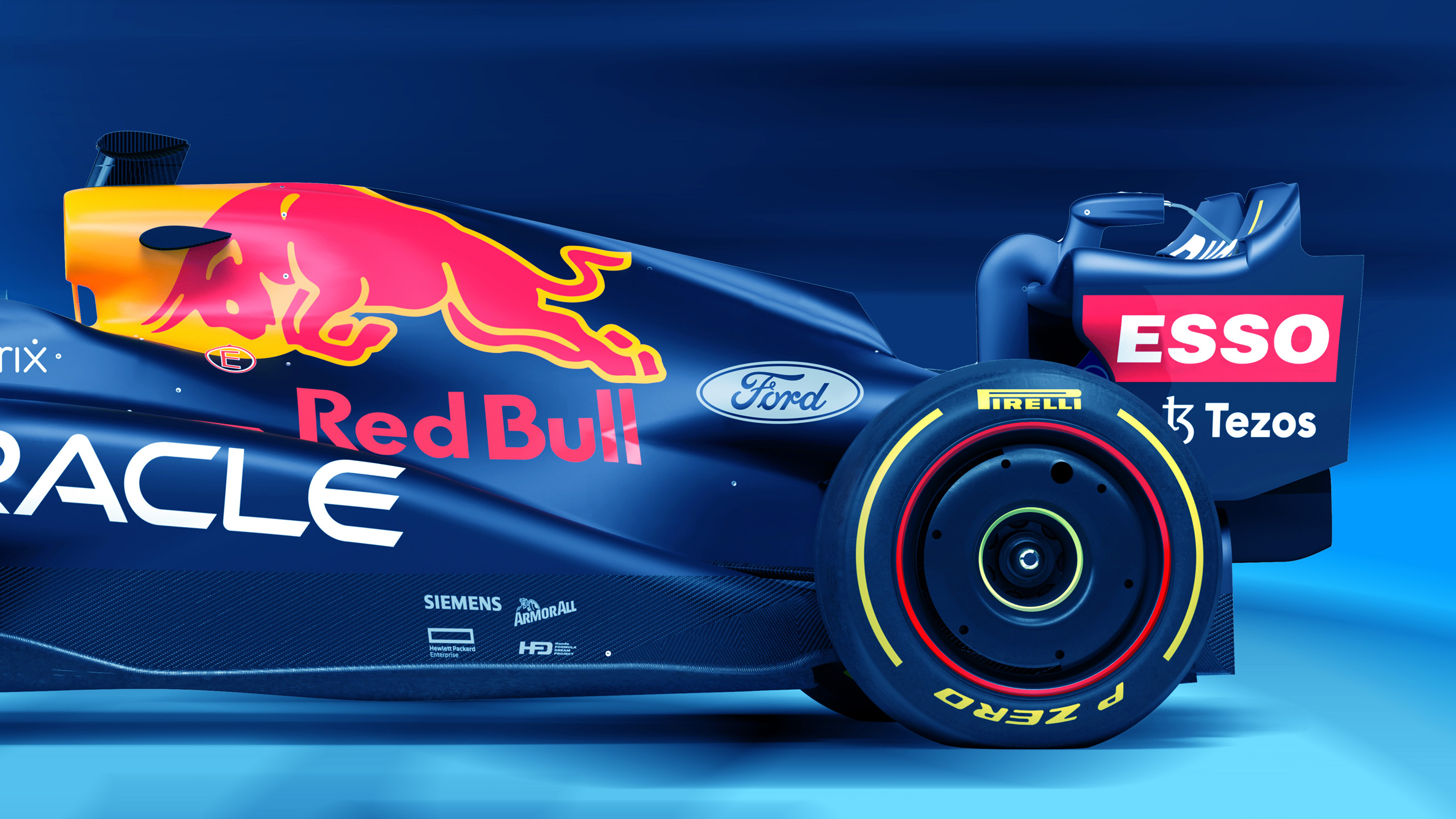

Ford is 3D-printing parts for the 2026 Red Bull F1 car

Ford's been getting CTRL+P-happy with parts

Ford’s motorsport team has 3D-printed over 1,000 parts in preparation for its 2026 F1 debut with Red Bull, creatively testing them with methods borrowed from aerospace. 3D-printed Top Gun anyone?

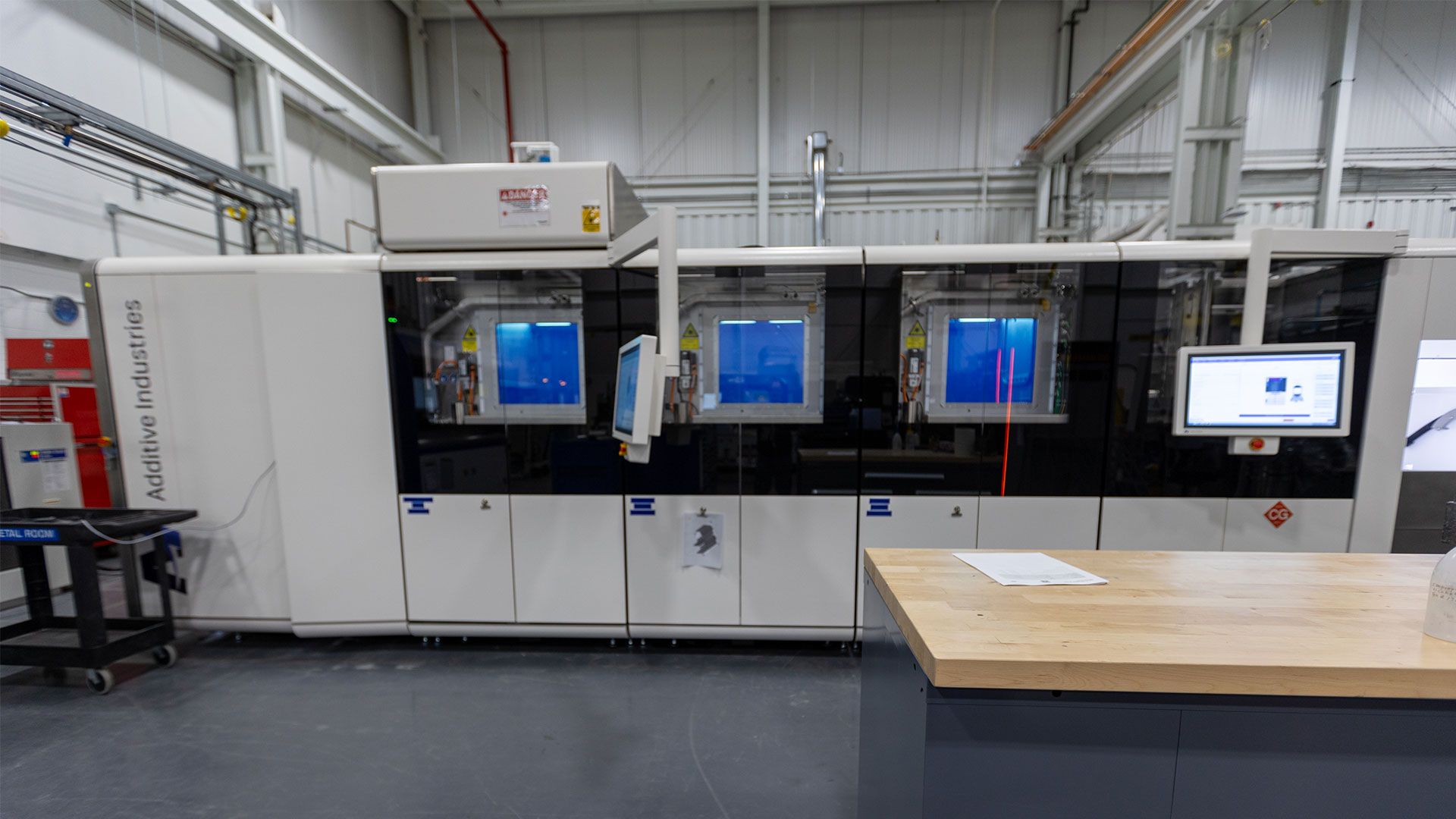

Components such as cold plates for batteries and cooling plates for other parts were printed and then put through X-Ray and CT scanners by the Non-Destructive Evaluation team. Which sounds like a fun team.

Christian Hertrich, chief powertrain expert at Ford Performance Motorsports, said: “It’s not things like nuts and bolts and easy stuff. These are complex metal and polymer parts that get tested to extremes so they can withstand races that average 200 miles an hour.”

To make parts tough enough for the extreme demands of F1, Hertrich explained that testing involves 3D scanning for mechanical strength, hardness and geometric compliance. Then getting the NDE team to give them a whirl in their fancy super scanners before they get sent to metrology, where they're tested for accuracy and precision. Then sending them off to Red Bull F1.

Ford explains these rigorous testing protocols have been created from various departments within the carmaker, and that such approaches are finding their way into road car development, too. Citing a glue issue on an F-150 headlight – the root cause of which eluded engineers for months – he said the NDE team brought their handy scanners and wrapped things up in a day. Nice mic drop moment.

Of course, additive manufacturing ('3D-printing' in IndustrySpeak) isn't new. Remember the Bugatti brake caliper, or this homemade V8 Aventador and this entire Czinger 21C? But Ford is definitely pushing the envelope by both sticking more of this stuff out on track, and catalysing a trickledown effect to consumer cars.

Projects like this HRE wheel demonstrate how 3D-printing gives engineers capacity to create shapes and forms impossible through traditional methods, and F1 engineers have long appreciated the speed of additive manufacturing, not to mention the lightweighting benefits.

Whether or not Ford's rapidly produced 3D-printed parts translate to rapid results out on track is yet to be seen. Roll on 2026.

Top Gear

Newsletter

Thank you for subscribing to our newsletter. Look out for your regular round-up of news, reviews and offers in your inbox.

Get all the latest news, reviews and exclusives, direct to your inbox.

Trending this week

- Car Review

BMW 1 Series