Nissan wants to make hybrids as cheap as petrol cars by 2026

Streamline production, slash manufacturing costs, cut consumer prices. Done

Nissan is working to knock a chunky 30 per cent off electrified powertrain manufacturing costs by 2026. A cut based on 2019 figures, the Japanese car maker hopes it’ll create a future powertrain standard that can be replicated more cheaply and get the price of electrified cars more on par with petrol ones.

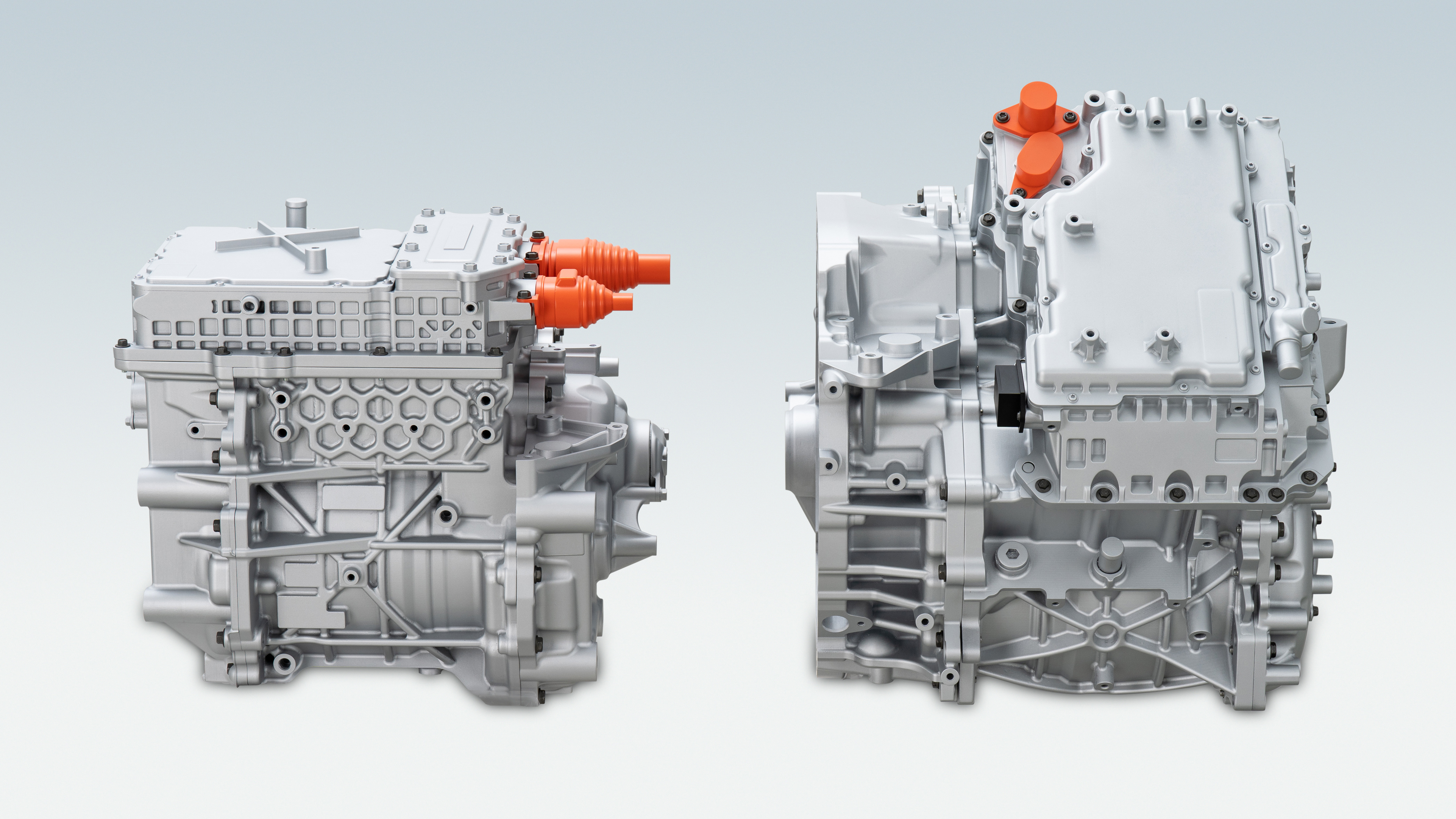

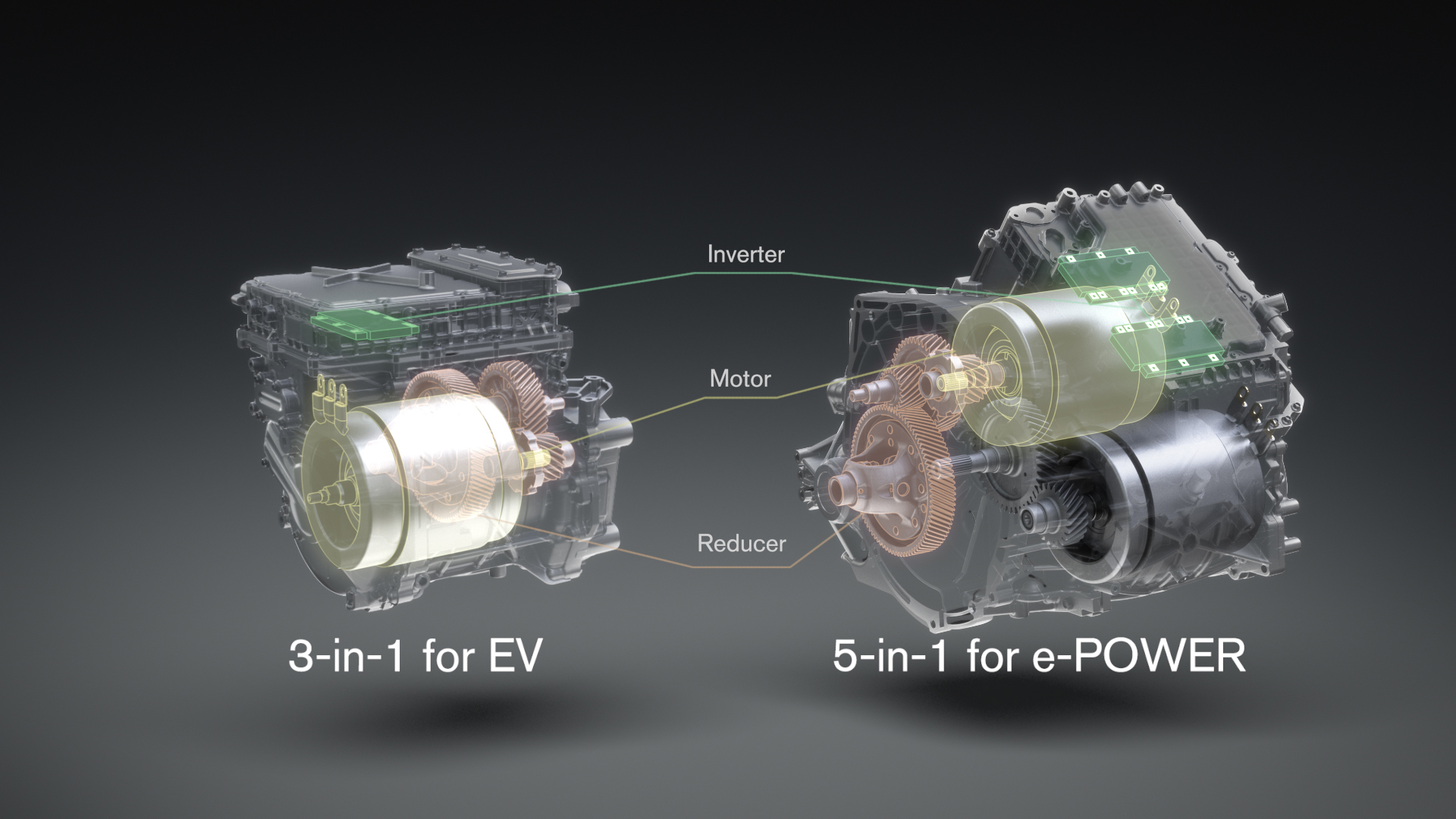

By using a modular system it calls ‘X-in-1’, the manufacture of its electric vehicle (EV) and e-Power core components can be streamlined to cut costs.

Such an approach can be scaled up or down, depending on the vehicle model and power requirements of the design. Yet, by keeping everything else pretty much the same, the powertrain can be configured on the same production line, thus reducing the production overheads.

Already Nissan has a 3-in-1 powertrain prototype - modularising the motor, inverter and reducer - for EVs. The planned 5-in-1 prototype integrates a generator and increaser for use in hybrid models, but the approach is clear to see; take the core components then bolt on the extras in a pre-conceived clever way.

The car maker is planning to make other reductions, too, specifically around the size and weight of each unit and to also reduce its reliance on rare earth materials to one per cent or less — both of which should also help make much-needed savings.

Top Gear

Newsletter

Thank you for subscribing to our newsletter. Look out for your regular round-up of news, reviews and offers in your inbox.

Get all the latest news, reviews and exclusives, direct to your inbox.

Trending this week

- Long Term Review

Life with a 500bhp BMW 550e: do you really need an M5?